SLA rapid prototyping applications

Release time:

Mar 28,2025

Source:

Integrating 3D printing into production

Whether it's accelerating prototyping, shortening lead times, or reducing the cost of outsourcing manufacturing tools, the production process benefits from 3D printing in many ways.

1. Pre-production

By 3D printing parts in-house, you can accelerate workflows, reduce iteration costs, tighten feedback loops, and verify part design and manufacturability, avoiding various supply chain-related delays.

LED light tubes manufactured by a lighting company, 3D printed using gray photopolymer resin.

A hygrometer prototype with both functional and aesthetic similarities to the finished product, 3D printed using flexible resin and black resin.

Rapid Prototyping

Use advanced materials to test concepts, communicate requirements, and verify design manufacturability. Before investing in expensive production tools, conduct small-batch or one-off custom production to conduct comprehensive on-site and internal testing.

A communication model from a mechanical design company, 3D printed using gray resin.

Communication Model

Physical models help communicate the complexities of 2D drawings and reduce the likelihood of errors and misunderstandings. Use 3D printed parts to clearly and accurately communicate various considerations of manufacturable designs with clients or other team members, such as available tooling, minimum radius requirements, and the number of processes required.

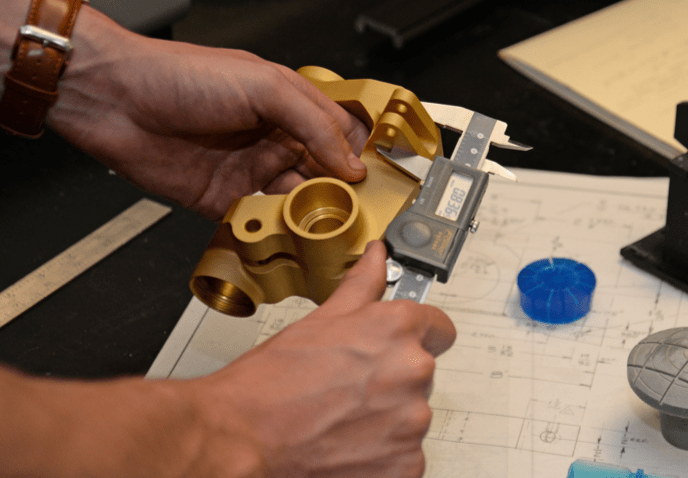

Components from a Beijing design company, used for production verification

Production Verification

Use 3D printed replacement parts or alternative parts to quickly configure assembly lines, assess the ergonomics of jigs and fixtures, and calibrate automated processes. Alternative parts can replace precision, expensive parts or sub-assemblies consumed in individual processes (such as secondary molding). Alternative parts can also be used to train machine operators, reducing the cost of using expensive original parts.

3D printing has become a very important tool for us. While it sounds a bit clichéd, the technology has indeed allowed us to think outside the box.

GUIDO JACQUES

Vice President of Operations

A&M Tool and Design company

2. Production Tools

Compared to outsourcing to external suppliers and using machined solid plastic or metal blocks to manufacture parts, in-house rapid manufacturing of inexpensive jigs, fixtures, and tools canShorten lead times by days or even weeksImprove business flexibility and significantly reduce costs.

Positioning jig printed from Tough Resin

Custom jig for Pankl Racing Systems, 3D printed using Tough Resin (high-toughness resin)

Jigs and Fixtures

By producing jigs and fixtures in-house, there is no need to consider minimum order quantities or cumbersome tool path programming. Instead, a wide range of material choices and low capital equipment costs allow production lines to reduce costs and increase flexibility. Using jigs and fixtures that improve assembly or quality assurance processes can continuously improve products and quickly and effectively address problems on the production line.

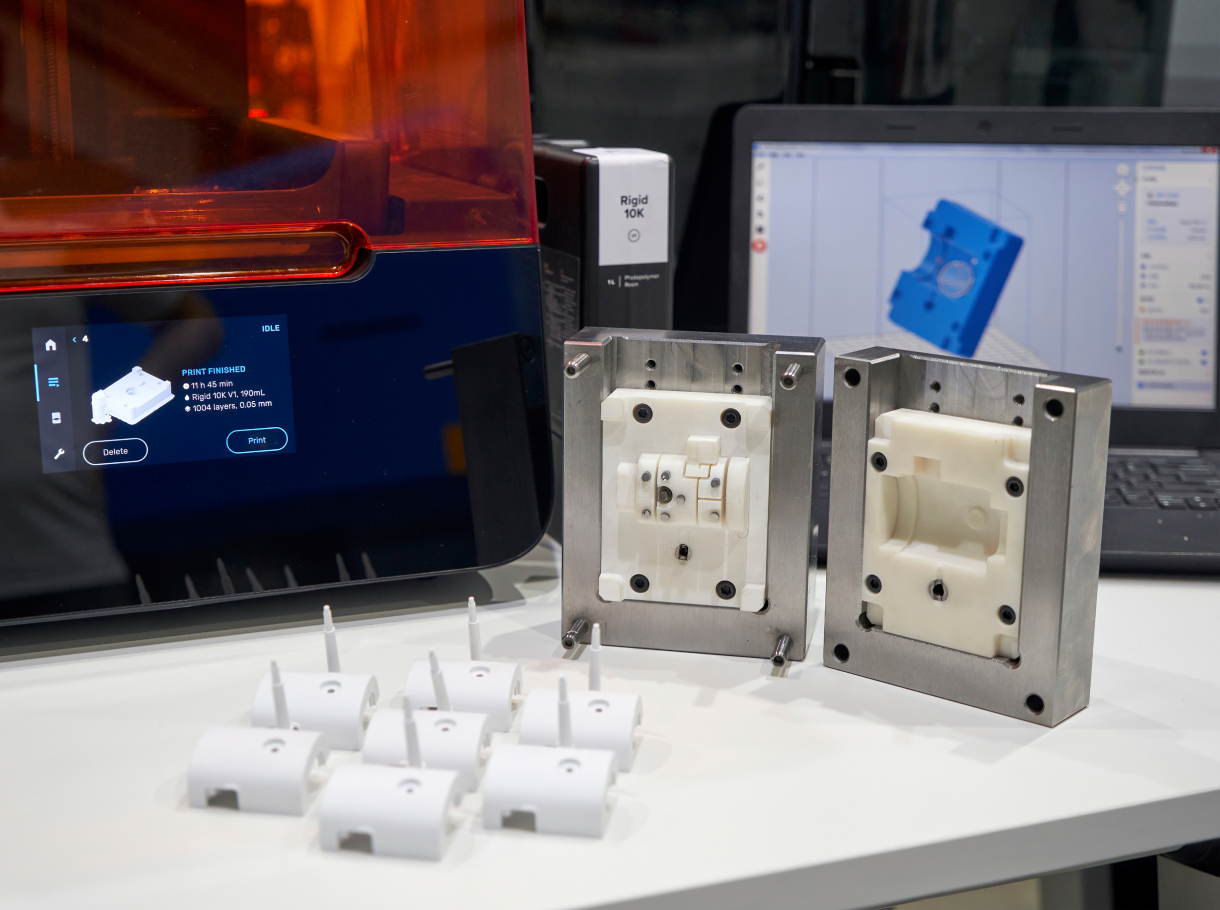

USB injection mold, 3D printed using high-temperature resistant resin

Tool Making

Manufacture custom tools that can withstand the harsh demands of the factory environment to help you solve challenging manufacturing problems. By directly printing tools for various applications (such as injection molding and CNC bending processes), you can verify manufacturing processes, solve DFM problems, and improve flexibility.

3D printed injection molding tools for short-run production

Injection Molding

Compared to traditional mold making, 3D printed injection molding molds for prototyping and small-batch production reduce costs and shorten lead times while ensuring that the parts produced are high-quality and repeatable.

If the process is outsourced to a traditional processing service provider, we must wait 6 weeks before production is completed. With 3D printing, simply send the same design to the printer, and the finished printed parts will be available the next morning.

3. Finished Parts

Whether it's a local foundry or a Fortune 500 company, 3D printed parts can reduce the time- and resource-intensive steps in their production processes. Cost-effective customization also brings unparalleled flexibility, allowing businesses to create more business opportunities.

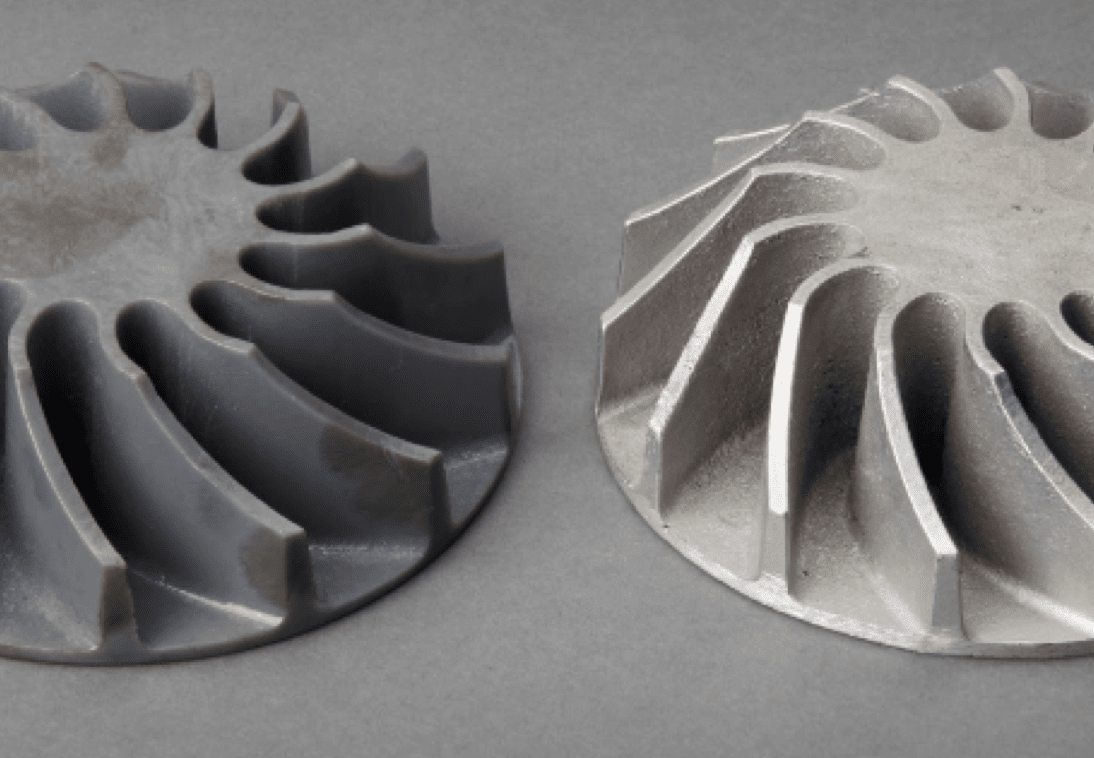

Printed model (left) and finished aluminum casting made from an open sand mold (right)

Metal Casting

High-precision polymer 3D printed parts are ideal for casting workflows. Compared to traditional methods, it reduces the cost of producing metal parts, offers greater design freedom, and requires less time. Foundries around the world have begun adopting 3D printing technology to manufacture models for direct investment casting, lost-wax casting, and sand casting molds.

Finished product of the robotic arm (left), its secondary molded core structure is made from a mold printed with transparent resin, then printed with black resin. On the right is a prototype of the finger, printed with flexible resin.

Small Batch Production

Using 3D printing for short-run production allows you to flexibly edit designs without investing heavily in mold making. This is also a cost-effective alternative for producing large quantities of final products.

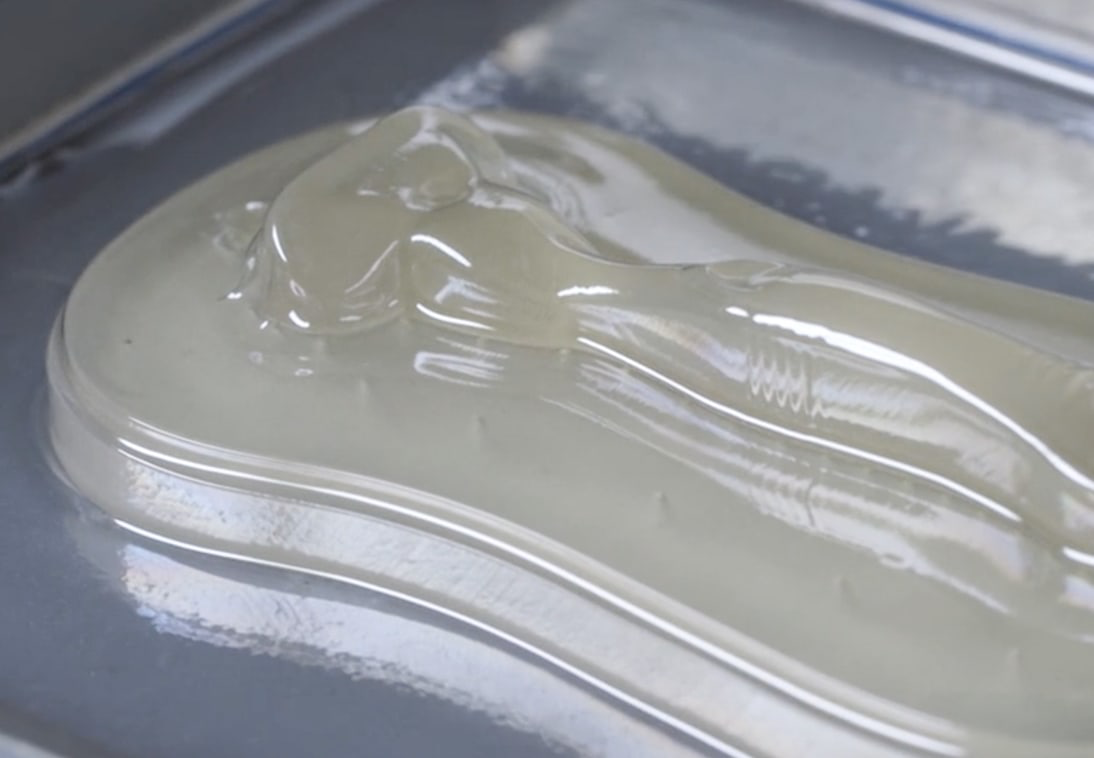

Razor thermoforming mold, 3D printed using high-temperature resistant resin

Test mold designs before investing in expensive tooling. Print ready-to-use molds and use them with adaptable materials in thermoset and thermoplastic workflows to manufacture low-volume injection molded, secondary molded, and cast components.

New Balance customized track spikes

3D printing technology allows you to produce a variety of complex designs without investing in expensive molds, or requiring significant time, energy, or materials. Automated 3D printing solutions help you mass produce personalized products to meet market demands. From custom surgical models and dentures in the medical industry to insoles and headphones in the consumer market,headphonesare all successful examples of mass customization.

Previous

Previous

Other Content

2025-08-10